|

| Diesel Motorcycle, Being Started and Built Around A Kubota Engine And Custom Frame From Kraft Tech |

Showing posts with label Engine. Show all posts

Showing posts with label Engine. Show all posts

Sunday, June 21, 2015

Diesel Motorcycle, Being Started and Built Around A Kubota Engine And Custom Frame From Kraft Tech

Thursday, April 4, 2013

The Flying Millyard Or The Coolest New V-Twin Motor

|

| Recognize the engine? Used to seeing it in this format, now check it out as a V-Twin |

Check out Cyril Huze's Blog for the original link and a lot of other great stories

Friday, June 29, 2012

11 Months, 3000 pictures and a lot of coffee...

Beauty is in the eye of the beholder and this beholder happens to have a an amazing sense of choreography and an eye behind the lens. In the words of Jon Stewart this is your moment of Zen.

"Started out as just a collection of snaps as I stripped down an engine

bought off ebay. (To replace my old engine, which had suffered

catastrophic failure). The snaps were so that I remembered how

everything went, so I could put it back together again.

Then I realised it'd be quite cool to make it an animation. found some suitable music, rekindled my ancient knowledge of Premiere, storyboarded it, shot it as I worked on the engine (my poor DSLR got covered in engine oil), this was the result.

The music is "In The Hall Of The Mountain King" from Edvard Griegs "Peer Gynt Suite"

I own a suitable license for this piece of music, supplied by Chris Worth Productions."

Then I realised it'd be quite cool to make it an animation. found some suitable music, rekindled my ancient knowledge of Premiere, storyboarded it, shot it as I worked on the engine (my poor DSLR got covered in engine oil), this was the result.

The music is "In The Hall Of The Mountain King" from Edvard Griegs "Peer Gynt Suite"

I own a suitable license for this piece of music, supplied by Chris Worth Productions."

Thursday, June 7, 2012

Wheels Through Time, New Photo Updates

About twice a year we will roll over to the Wheels Through Time museum in Maggie Valley and just gawk at the history and amazing bikes in their building. Every time I go through I try to find a new angle on the photos and see something new to shoot. As many times as I have been its getting harder, but luckily a plethora of their bikes change out and they are continually adding new pieces to their evolving collection.

Check out the Wheels Through Time museum

Check out the Wheels Through Time museum

|

| Old Picture cut out on the wall with Illinois License plate from 1930 |

|

| Original Excelsior Motorcycle from Chicago, late 1918 or early 1920's |

|

| Superior Spark Plugs |

|

| Knucklehead and Panhead on the workbench at the Wheels Through Time museum |

|

| Harley Davidson pedal start single BA style engine from the mid 1920's |

|

| Vintage dirt track racing, photo of a photo |

|

| Indian split tank Chief dash |

|

| Indian Motorcycles gas tank |

Labels:

Americana,

Chopper,

Custom,

Engine,

Excelsior,

Harley Davidson,

Indian,

Knucklehead,

Motorcycle,

Piston,

Vintage,

Wheels Through Time Museum

Friday, May 18, 2012

Thirteen Hours Of Engine Porn?

What if we told you there is a new star in a film, that is thirteen hours in length and the action is ongoing like a Lord Of The Rings adventure, would you be interested to watch? Oh damn, we might have lost ya at the words, thirteen hours, but we dig the bold vision that is being introduced.

Jesse Cain, a film maker and amateur mechanic, has decided to break down the sexy siren within his film, which just happens to be a 1982 Volkswagen Rabbit engine and get it back into working order through a carthatic and enduring process film. Check out a ten minute clip below and see what you think, as it is clearly a different approach.

|

| Jesse Cain's1982 Volkswagen Rabbit engine and its thirteen hours of voyeur fame |

Instead of Steve McQueen performing multiple stunts, the film stars the engine of a 1982 Volkswagen Rabbit and a pair of greasy hands. Like the still shown above, all the action consists of close ups of the engine being methodically taken apart and put back together again — triple-X rated pornography for the folks over at VW Vortex.

Filmmaker Jesse Cain is both the man behind the camera and the mechanic working on the car, and the project took him over two years. He said he originally wanted to film himself working on an iconic piece of Detroit iron, but chose a broken-down Rabbit since his name was already on its title.

“I decided to be thrifty in the recession environment and fix what I already owned,” Cain said. “The movie is entirely shot with close-ups, each shot composition and duration determined by the size, shape and difficulty of removing or installing each part.” You can watch ten minutes of it in the video clip below.

Cain doesn’t have any illusions about his own abilities as a mechanic, admitting to multiple mistakes he made throughout the process. “It would be fun to sit with an ASE certified mechanic and have him or her critique my work,” he said. “I’m pretty sure there would be some big laughs and horrified cringes at times.”

The project started as part of a larger film that Cain had planned, about a boy who fixes a long-neglected car after his family’s home goes into foreclosure. After shooting the scenes with the Rabbit, however, Cain realized the car was the true star.

“I started filming tests of how I imagined the engine scenes would look, and after watching the dailies of these tests I realized that I had already started shooting the film I wanted to make,” he said.

The result was a film that took as long as Cain spent working on the car. “Instead of relying on the usual tricks of filmmaking — jump cuts, time lapse, or simple editing of action — I left the camera rolling and showed the entire process,” he said. “The work involved took me 13 hours, three minutes on camera. It’s kind of a rejection of internet culture and immediacy.”

So far, response has been positive. New York City’s Anthology Film Archives screened Parts and Labor last weekend, offering a special ticket that allowed audience members to come and go as they pleased. The program even touted that the film “out-Warholed Andy.”

“Most people find it very meditative,” Cain said. “It’s very easy to settle into it for a while and become involved in the minutia of the operation. Others say it’s surprisingly riveting. The struggle and success of each shot has its own narrative arc.”

In other words, it’s just like working on a car."

Tuesday, February 7, 2012

The Unauthorized "Scott Free" Technique for Changing Buell Isolators

How often have you spent hours working to take apart a piece of machinery and walked away frustrated that the manual in no way shape or form was created by the person actually working on the object in question? Yes, this happens all the time unfortunately. Our Buell build left us hanging this past Saturday with utter frustration over the isolators on the swingarm. Our chain block was put into overtime lifting, descending, lifting, hanging, banging and cussing like there is no tomorrow in frustration over removing these damn isolators that dampen the vibration where the swingarm and motor mount connect to the frame on early Buell models.

When in doubt, search out the internet and type in a myriad of questions on how to fix what ya need. After a few queries we found several options and one amazing link lead us to the page of Daniel C. Starr and his ingenious tool. Below is a repost from Daniel's site and his home made custom tool for replacing the isolators. If only we could have found this before we started to tear right into the bike, doh!

|

| Tube frame Buell islotator that is damaged and needs replacing |

"Tube-frame Buells use what are more or less the same rubber biscuit "isolators" as the Harley touring bikes (no surprise there; Erik Buell is said to have invented the system). And, from time to time, these isolators wear out. The symptom I noticed was a lot of vibration through the footpegs, especially when the bike was heavily loaded (i.e., with gear for the week-long trip to Deals Gap I was about to depart on) and hitting any kind of a dip in the road. And when they start failing, riding is not an option--these things are chunks of rubber and metal that are glued together and support the weight of the bike and rider in a shear mode. When they start coming apart, there ain't nothing keeping your ass off the pavement. The photo at right shows just how far my right-side isolator had gone by the time I discovered it was failing. The end plate (which nestles into the frame) had separated from the rubber over close to half the isolator's circumference. Not at all a good thing. I had to replace these puppies right now. Here's how I did it.

On

some bikes (the Harleys, the S2 and earlier models, and the X1

Lightning), the rear isolators are held in place by a bolt-on plate that

lines them up and squeezes them into position. On these bikes,

replacing the suckers is easy. But on some models--S1 Lightning, S3/S3T

Thunderbolt, and M2 Cyclone), the isolators are slipped into recesses in

the frame before the engine and swingarm block are lifted in from

below. That is, there's no removable piece providing access.

The shop manual says you're supposed to remove the engine from the frame to change the rear isolators. Aiee! most customers say in response. So various imaginative people have come up with schemes to free the rubber biscuits without having to hang the frame from an engine hoist while strapping the motor to a floor lift (and by the way, disconnecting every oil hose and half the electrical wiring on the bike). We had some motivation here.

Oh, and of course you may not be doing this because the isolators have died; you may simply want to replace a worn drive belt (especially if your belt was set up too tight by the selling dealer, which many tube frame Buell belts were). That's what led me to develop this scheme. Word to the wise: if you're going to go to the effort (even the significantly reduced effort under my scheme) to remove the isolators, you might as well replace all the stuff that's replaceable here. In other words, if the only thing "bad" appears to be the belt, replace the isolators at the same time; if the isolators look bad and the belt looks OK, replace the belt anyway. There's nothing worse than having to rip the bike apart a year later because a belt or an isolator that looked OK the last time you had the bike apart is now going south on you. How did I learn this? Because I replaced the belt at 40,000 miles and didn't replace the isolators while I had things apart, of course...

Also, keep in mind that I'm not a Buell employee, and Buell didn't approve of this procedure (or even look at it, far as I know). It worked for me, and it was a lot easier than the procedure found in the manual--but remember that 30 years ago some aircraft mechanics were saying the same thing about using a fork lift to remove/install the engines on a DC-10, and we all know how that turned out. I make no warranty that this procedure will work for you. Be careful out there...

So, with that in mind, let's get started:

Step 1. Get the bike up in the air and remove the back wheel, hugger and belt guards. Make sure you have plenty of room to move around beneath its nether regions.

Step 2. Put a jack (preferably one with wheels) under the transmission to support its weight, and then remove the two big allen bolts that hold the isolators to the swingarm block. These are 1/2" head allens. If you don't have an allen socket of that size, Lafayette has a cheap substitute: buy a 2" long by 1/2" "coupler nut" and stick it into a (six point) 1/2" socket. Voila! An Allen substitute! Be careful removing the bolts; you don't want to mess up the threads. In particular, make sure you've got the jack adjusted so that the bolts aren't snagging on the isolator base plates as you take 'em out. It's surprisingly easy to monge the threads.

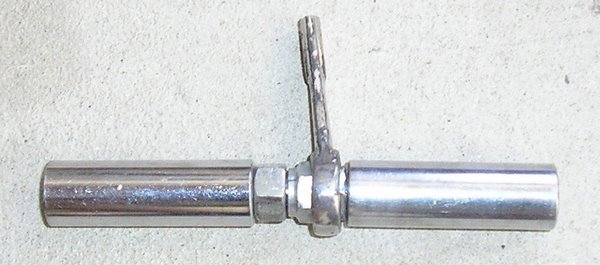

Step 3. Assemble the spreader tool shown below (Note--click on any of these pictures to expand it). The center piece of the tool is about six inches of 3/8" threaded rod from the hardware store. The pieces on it, from left to right, are a 3" piece of stout tubing (I used a leftover Harley Sportster turn-signal stalk, thereby keeping the whole thing an "Authentic Harley Special Tool"), a regular 3/8 nut, a jammed-together pair of 3/8" nuts (one of them's a locknut; it's inside the wrench and the two are held together with Loctite. In the best of all possible worlds, the central nut would be welded to the threaded rod), half of a 9/16" box wrench, and the other turn signal stalk.

The shop manual says you're supposed to remove the engine from the frame to change the rear isolators. Aiee! most customers say in response. So various imaginative people have come up with schemes to free the rubber biscuits without having to hang the frame from an engine hoist while strapping the motor to a floor lift (and by the way, disconnecting every oil hose and half the electrical wiring on the bike). We had some motivation here.

Oh, and of course you may not be doing this because the isolators have died; you may simply want to replace a worn drive belt (especially if your belt was set up too tight by the selling dealer, which many tube frame Buell belts were). That's what led me to develop this scheme. Word to the wise: if you're going to go to the effort (even the significantly reduced effort under my scheme) to remove the isolators, you might as well replace all the stuff that's replaceable here. In other words, if the only thing "bad" appears to be the belt, replace the isolators at the same time; if the isolators look bad and the belt looks OK, replace the belt anyway. There's nothing worse than having to rip the bike apart a year later because a belt or an isolator that looked OK the last time you had the bike apart is now going south on you. How did I learn this? Because I replaced the belt at 40,000 miles and didn't replace the isolators while I had things apart, of course...

Also, keep in mind that I'm not a Buell employee, and Buell didn't approve of this procedure (or even look at it, far as I know). It worked for me, and it was a lot easier than the procedure found in the manual--but remember that 30 years ago some aircraft mechanics were saying the same thing about using a fork lift to remove/install the engines on a DC-10, and we all know how that turned out. I make no warranty that this procedure will work for you. Be careful out there...

So, with that in mind, let's get started:

Step 1. Get the bike up in the air and remove the back wheel, hugger and belt guards. Make sure you have plenty of room to move around beneath its nether regions.

Step 2. Put a jack (preferably one with wheels) under the transmission to support its weight, and then remove the two big allen bolts that hold the isolators to the swingarm block. These are 1/2" head allens. If you don't have an allen socket of that size, Lafayette has a cheap substitute: buy a 2" long by 1/2" "coupler nut" and stick it into a (six point) 1/2" socket. Voila! An Allen substitute! Be careful removing the bolts; you don't want to mess up the threads. In particular, make sure you've got the jack adjusted so that the bolts aren't snagging on the isolator base plates as you take 'em out. It's surprisingly easy to monge the threads.

Step 3. Assemble the spreader tool shown below (Note--click on any of these pictures to expand it). The center piece of the tool is about six inches of 3/8" threaded rod from the hardware store. The pieces on it, from left to right, are a 3" piece of stout tubing (I used a leftover Harley Sportster turn-signal stalk, thereby keeping the whole thing an "Authentic Harley Special Tool"), a regular 3/8 nut, a jammed-together pair of 3/8" nuts (one of them's a locknut; it's inside the wrench and the two are held together with Loctite. In the best of all possible worlds, the central nut would be welded to the threaded rod), half of a 9/16" box wrench, and the other turn signal stalk.

|

| Custom Buell isolator separator tool |

This is what it'll look like when it's assembled and ready to go:

|

| 3/8ths threaded rod, jam nuts loctite together, 9/16th wrench, steel sheath = Buell isolator tool |

Step 4. Slither up under the rear end of the bike, taking a 1/2" and 9/16" wrench and the tool you just fabricated with you. Remove the 9/16" bolt that fastens the turnbuckle to the swingarm carrier (this allows the engine and transmission to move side to side in the frame). Then remove the 1/2" bolt that holds the battery ground strap to the swingarm carrier. You'll find the hole goes all the way through the boss on the swingarm carrier, and it's tapped all the way through. So re-install the bolt from the left side, so that about 1/4" of it sticks out the right side of the boss. This provides a pin for the left end of the special tool to align on.

Step 5. Brace the cut-down 9/16" wrench part of the tool against the top of the swingarm carrier, and turn the nuts (fingers should be adequate) until the other end of the tool is pressed up firmly against the inside of the frame just above the right isolator. See the picture below:

|

| Notice the red bar, need extra torque, use the handle of a your portable car jack |

Step 6. Then, as the picture above also shows, put a big long wrench on the first nut (the one that presses up against the turn signal stalk on the left end of the tool) and turn this nut to spread the tool out and shift the engine/trans/swingarm carrier to the left. This is not actually spreading the frame; it's just compressing the left isolator. You will need to apply a lot of torque, which is why I put a long lever (a jack handle, actually) on the wrench. The cut-down wrench that's a part of the tool keeps the threaded rod from turning. Keep turning the wrench and extending the tool until you can pop out the right isolator, as seen below:

|

| Buell isolator tool, used effectively to drop out the isolators for replacing |

Notice how you've shifted the engine/trans/swingarm carrier about a quarter inch to the left--you can see this in the misalignment between the adjustment turnbuckle and the hole in the boss on the swingarm carrier. This picture also clearly shows how the cut-down 9/16" wrench is braced against the top of the swingarm carrier to keep the lock nut (and the threaded rod) from turning.

Step 7. Turn the nuts on the tool the other way (the cut-down box wrench part will flip around and brace itself against the swingarm), until you can remove the tool.

Step 8. Give the swingarm a yank to the right, and the left isolator will drop out. Now that you've got both isolators out of the way, this is a real good time to run a thread-chaser tap down the holes in the swingarm pivot. Remember that these pieces are assembled with heavy-duty red Loctite at the factory, so there's going to be some residue in there that could make it hard to get the bolts started when you re-assemble this piece. So clean those threads up now!

Step 9. Slip the new left isolator into place. Make sure it's aligned properly (see your Buell service manual). Reinstall the special tool, and repeat step 5 until you've compressed the (new) left isolator enough to slip the new right isolator into place. Make sure the belt's in the right place before you install the new isolator; the last thing you want to do is button up the job and discover the belt's dropped out! (Matter of fact, given that you've got the isolators off, inspect the belt closely--if it's even remotely near needing replacement, slip in a new one now. You'll thank yourself later!)

Step 10. Repeat step 7 and remove the special tool. You'll probably find the threads on the threaded rod are a bit monged up by now, so you may need an extra wrench to keep the rod from turning in strange ways.

Step 11. CAREFULLY start the allen bolts through the isolators and into the swingarm pivot. This can be tricky. You may have to fiddle with the jack a bit to align things properly. Be patient; you don't want to mess up the threads. The last time I did this, I found that the passage of time (and previous removal/replacement of the bolts when I did a belt replacement two years ago) had messed the threads up slightly. A quick cleanup with a 1/2" SAE fine tap solved the problem, and everything went together nicely. Don't forget the Loctite! Once both bolts are started, and you've again checked that the isolators are in the correct alignment, tighten the piss out of the bolts, to whatever monstrous amount of torque the manual specifies (about four grunts, if I recall correctly).

Step 12. Re-install the turnbuckle to the swingarm carrier. You may need to give the swingarm a little shove one way or the other to get things lined up. Re-install the ground strap (remember it bolts to the right side of the boss). Re-install belt guards, hugger, and back wheel. Lower the bike, give everything one last check, and you're ready to go."

- Daniel C. Starr

Labels:

Buell Motorcycles,

Cradle,

Engine,

Erik Buell,

Harley Davidson,

Isolator,

Swingarm,

Vibration

Monday, November 28, 2011

Machining The World's Smallest V-12 Engine

Hobbyists come in many forms, but ones that we have some of the utmost respect for are those mad machinists that produce small scale working engines. Its one thing to go and buy a model RC monster truck or car and assemble it. Then its another beast for those of ya that actually machine all your own working parts and make it run. Yes, we can easily call that level of patience a zen machine master.

Monday, October 17, 2011

Why Sound?

The world around us is enveloped with sounds, textures, vibrations and basically life going about its business all around us. If we were to drop dead would everything just stop? No way in hell as we are just a blip amongst all the energy constantly moving about.

Sound is very important to us in many forms. It could be that perfect rhythmic idle of our now recently sold cafe racer, the high speed roar of our twin cam motor begging for more throttle or one of the many bands we work with honing in on the perfect harmony to whip fans into a frenzy.

When it comes to the sounds we push out to the world at large, we want the best. To hell with putting out mundane crap or things that just don't work. This is why anything involving us is always running and is well engineered. We take pride in perfecting our products and working with those individuals that push through to new boundaries.

If you have noticed the music player over on the right side of this here page, it is created in conjunction with soundcloud.com. They are an amazing resource for digital streaming music and we highly endorse using their service. Without their fantastic service we would not be able to track our label roster being played or make it so easy for fans to listen to new music within our site. Have a look at a video by soundcloud about sound. It's a contemporary look at what we know of and think about sound and how intrinsically we are intertwined.

If you have noticed the music player over on the right side of this here page, it is created in conjunction with soundcloud.com. They are an amazing resource for digital streaming music and we highly endorse using their service. Without their fantastic service we would not be able to track our label roster being played or make it so easy for fans to listen to new music within our site. Have a look at a video by soundcloud about sound. It's a contemporary look at what we know of and think about sound and how intrinsically we are intertwined.

Go on over to the right side of this page and play some of those tracks and explore soundcloud

Wednesday, June 29, 2011

Haynes DIY Manuals Are Now Downloadable

How often have you been in your local bookstore and naturally graduate towards the automotive section? I am guessing it might be the only spot you go to besides checking out the magazines. If that is the case then you are in luck knowing that the famous Haynes DIY manuals are now going to be offered for sale as pdf downloads online. This is a great day for anyone needing a parts list or cure for their ailing jalopy. Best aspect about their online roll out of the manuals is they will also be available as e-readers and for mobile devices. Whether it be a vintage Porsche, a Ford Pinto, old Harleys or just about anything motorized the Haynes Manuals are available.